A Parametric Approach to Optimizing Building Construction Systems and Carbon Footprint: A Case Study Inspired by Circularity Principles

Abstract

:1. Introduction

- How to evaluate resource efficiency and the circular economy concepts applied in this building?

- What makes a construction system carbon neutral and resource-efficient?

- To what extent can the design of an office building apply principles of circularity in construction?

1.1. State-of-the-Art Research on Circularity and Environmental Impact

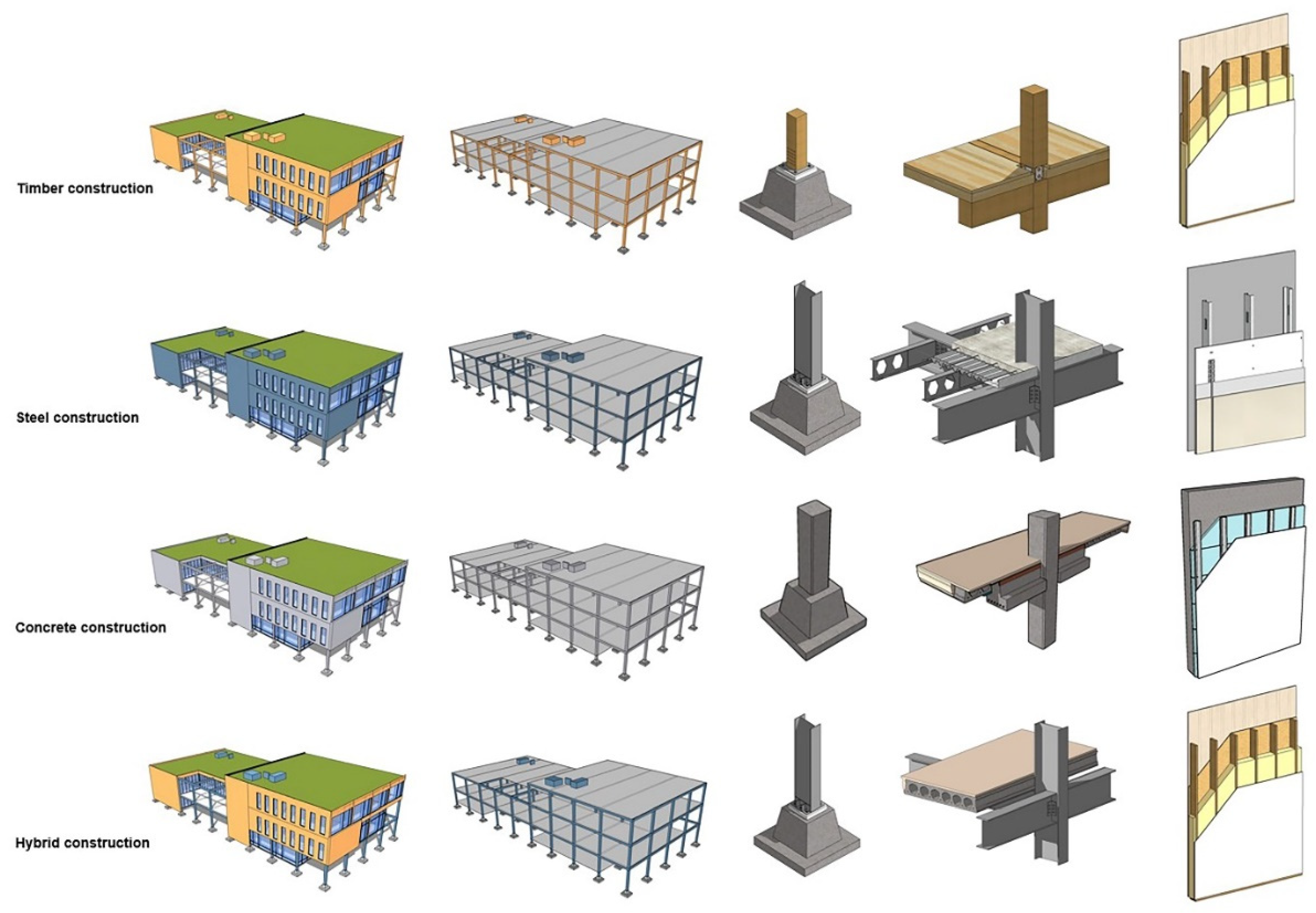

1.2. Application of Different Construction Systems and Materials

1.3. Objective

- Eliminate waste and pollution; it is crucial to consider waste and pollution as flaws in the design, not as inescapable by-products of the things that we make.

- Circulate products and materials; making and designing things to last forever is not the only solution; the products can be designed to be reusable at their highest value.

- Regenerate nature; we can boost the natural resources by returning nutrients to the soil, where everything will feed something else.

- Support the early design decision-making.

- Evaluate the circularity principles in timber construction.

- Adopt a parametric analytical approach to evaluate and compare different structural materials.

- Providing recommendations for circular building design for mid-size (above 1000 m2) office buildings.

2. Methodology

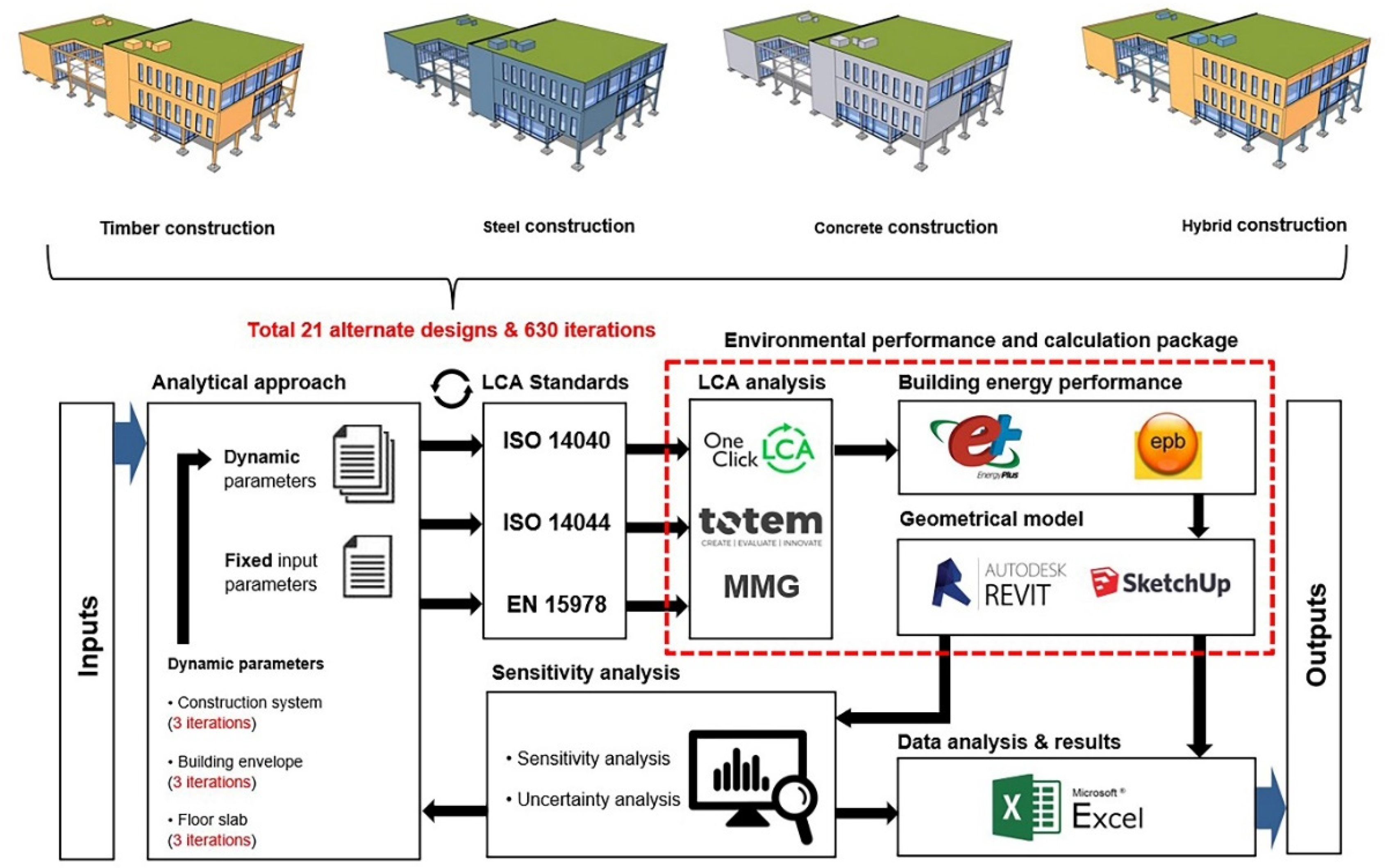

2.1. Analytical Approach

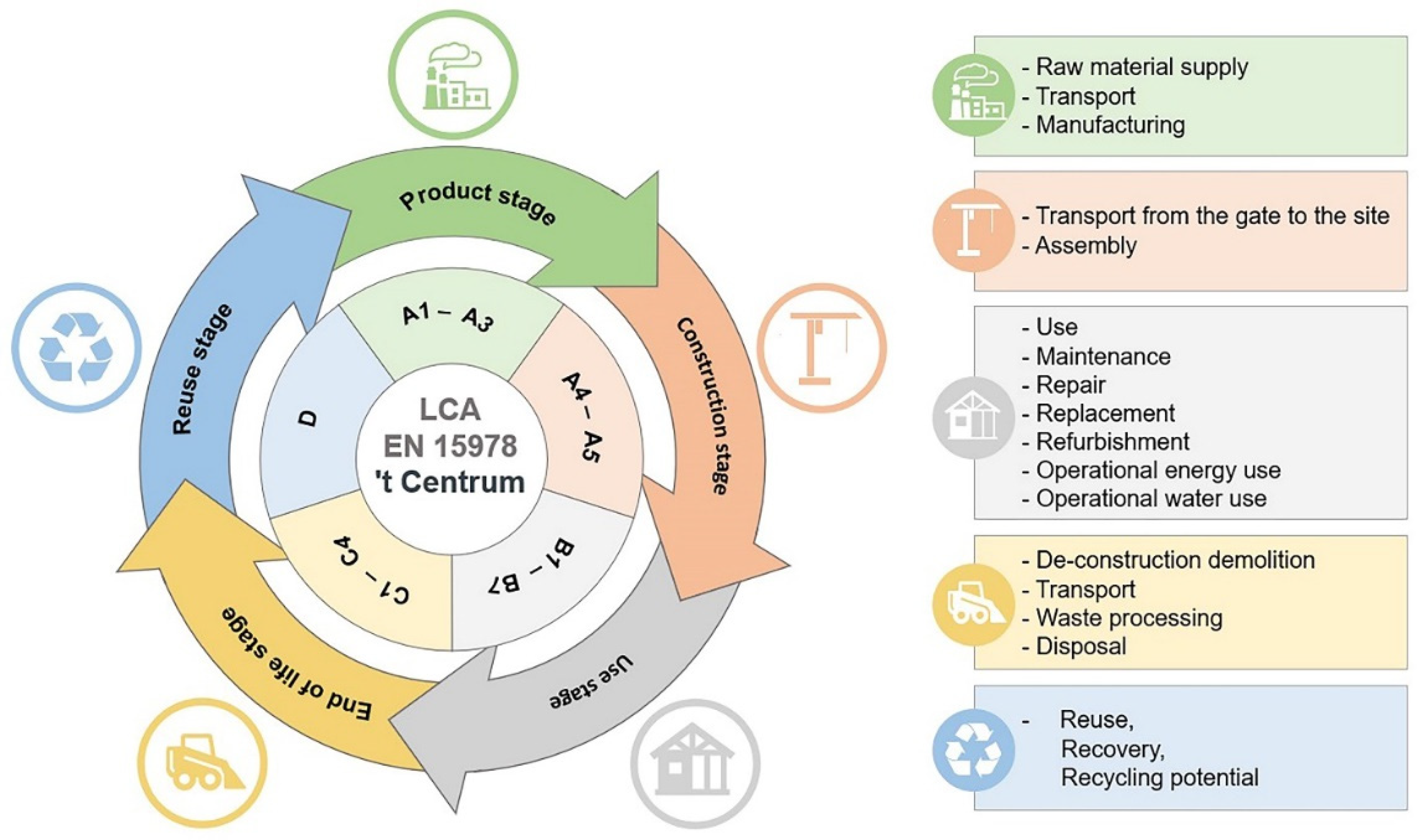

2.2. Life Cycle Standards and System Boundary

2.3. Functional Unit Study Tools and Indicators

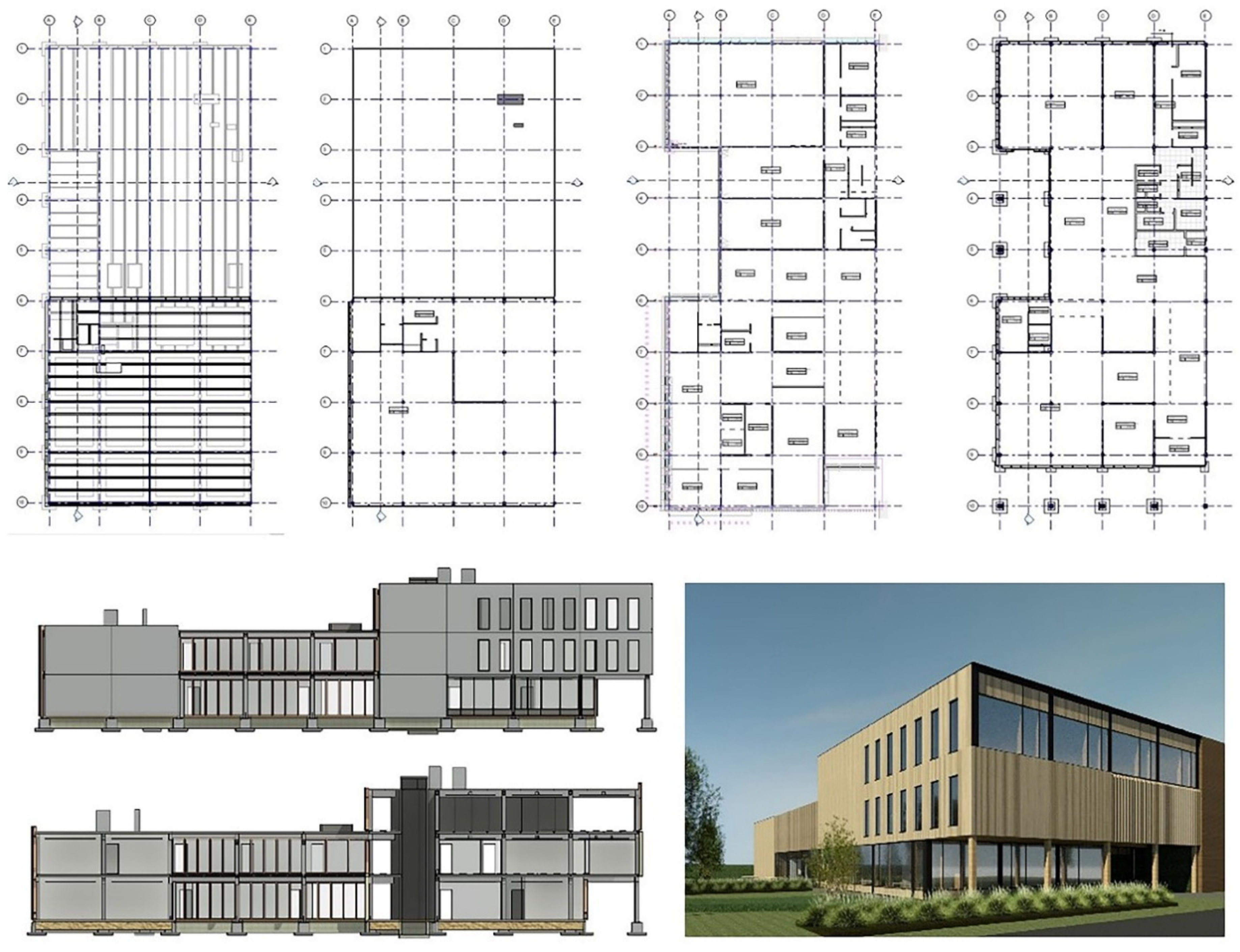

2.4. Case Study and Input Parameters

2.5. Life Cycle Inventory

2.6. Environmental Performance and Calculation

2.6.1. Geometrical Model

2.6.2. Building Energy Performance Modeling

2.6.3. Building Life Cycle Analysis

- to analyze the environmental impact of building materials according to an objective and scientific-based evaluation method.

- to optimize a design to reduce the environmental impact of the materials;

- to support the architects, clients, etc., to decide in the design stage.

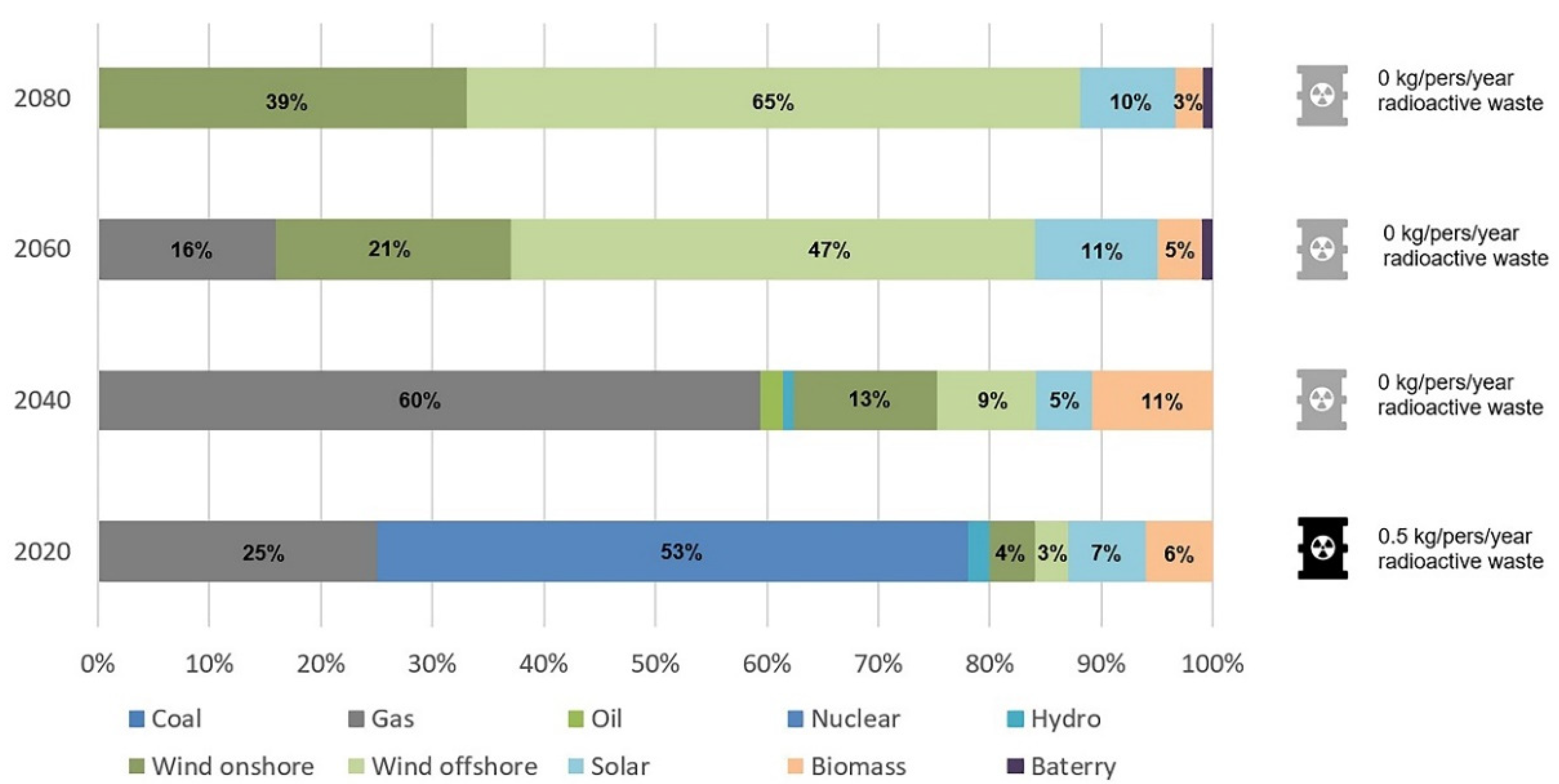

2.6.4. Operational Carbon Emissions

- A: low- and intermediate-level short-lived waste (working clothes, gloves, safety shoes, masks, laboratory waste, etc.).

- B: low- and intermediate-level long-lived waste (residual products from the processing of fuel, filters from the primary cooling circuit, etc.).

- C: high-level waste (irradiated fuel).

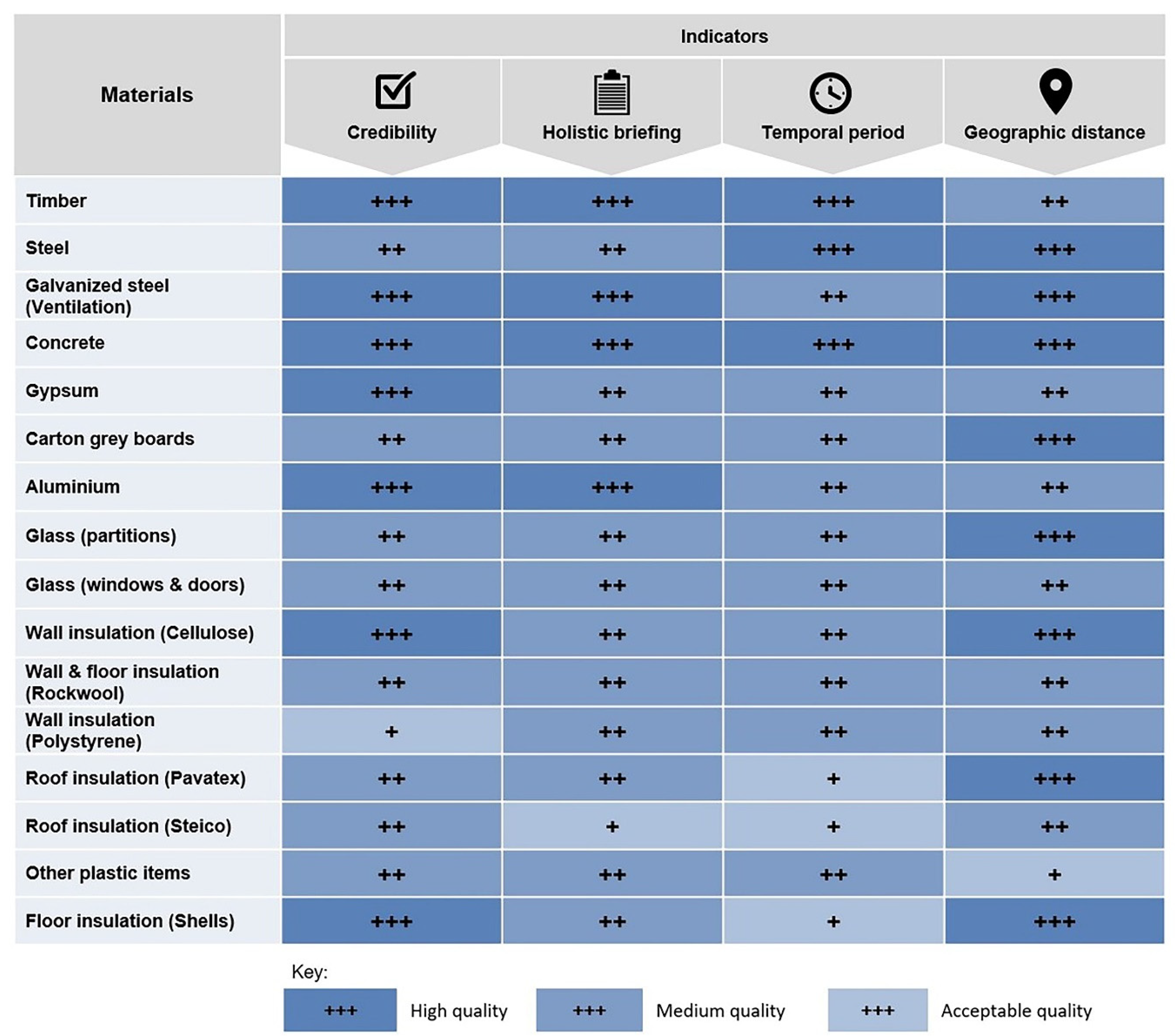

2.7. Data Quality and Validation

2.7.1. Data Sources

2.7.2. Data Quality Assessment

- Credibility (verified data based on measurements, assumptions, or estimation).

- The holistic briefing (representative data from the sites relevant for the market considered, over an adequate period to even out normal fluctuations).

- Temporality (the difference of the period of the dataset).

- Geographic distance (the difference of the geographic distance that allows verification and observation to ensure the validity of the dataset).

- Conducting focus group discussions and workshops.

- Intensive contact with suppliers and visits to manufacturers to determine the stages of production and transportation methods based on self-observations.

- Contacting members of the TOTEM database and the Belgian Building Research Institute (BBRI) members to learn more about the innovative materials used in the project and search for EPDs.

- Conducting site observations and regular site visits of the construction site every week.

2.7.3. Sensitivity analysis

2.7.4. Uncertainty Analysis

3. Results

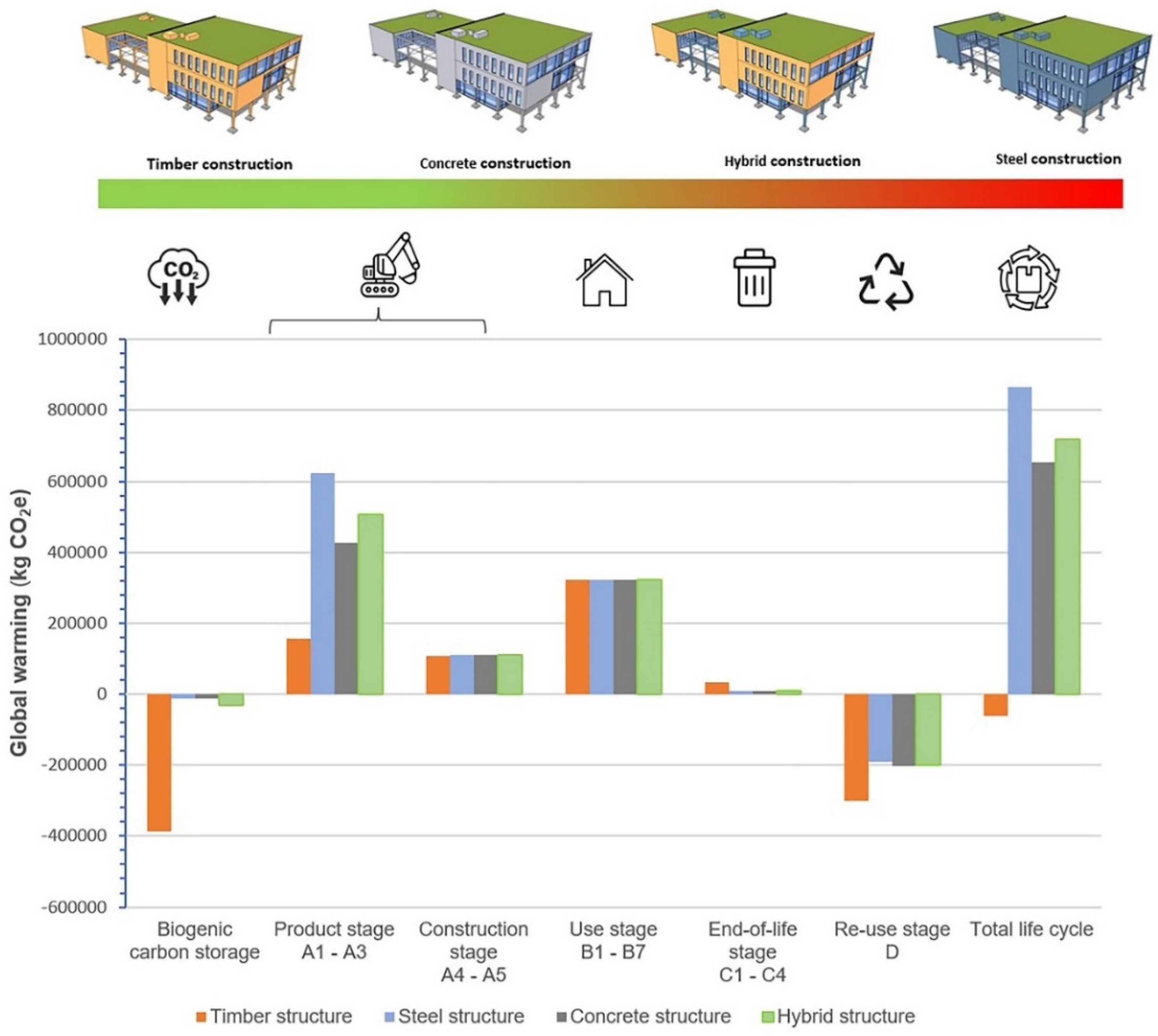

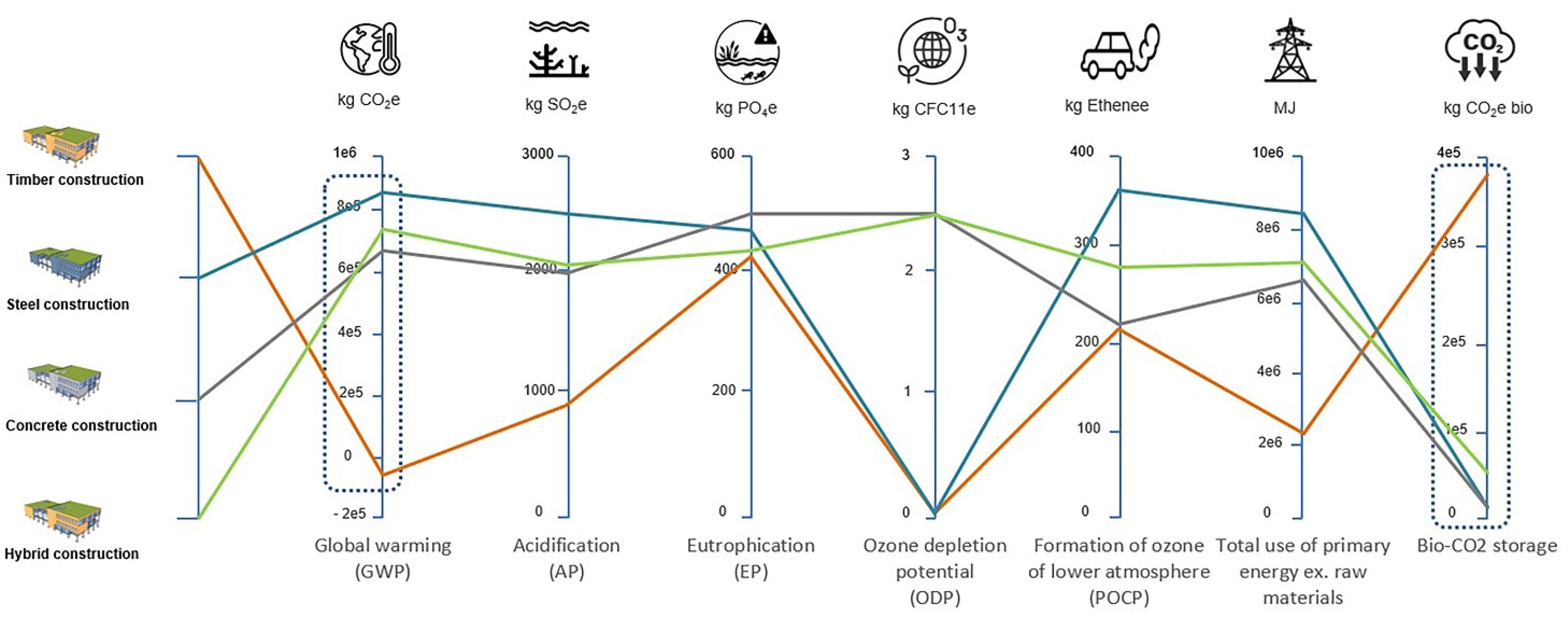

3.1. Environmental Impact and Carbon Footprint

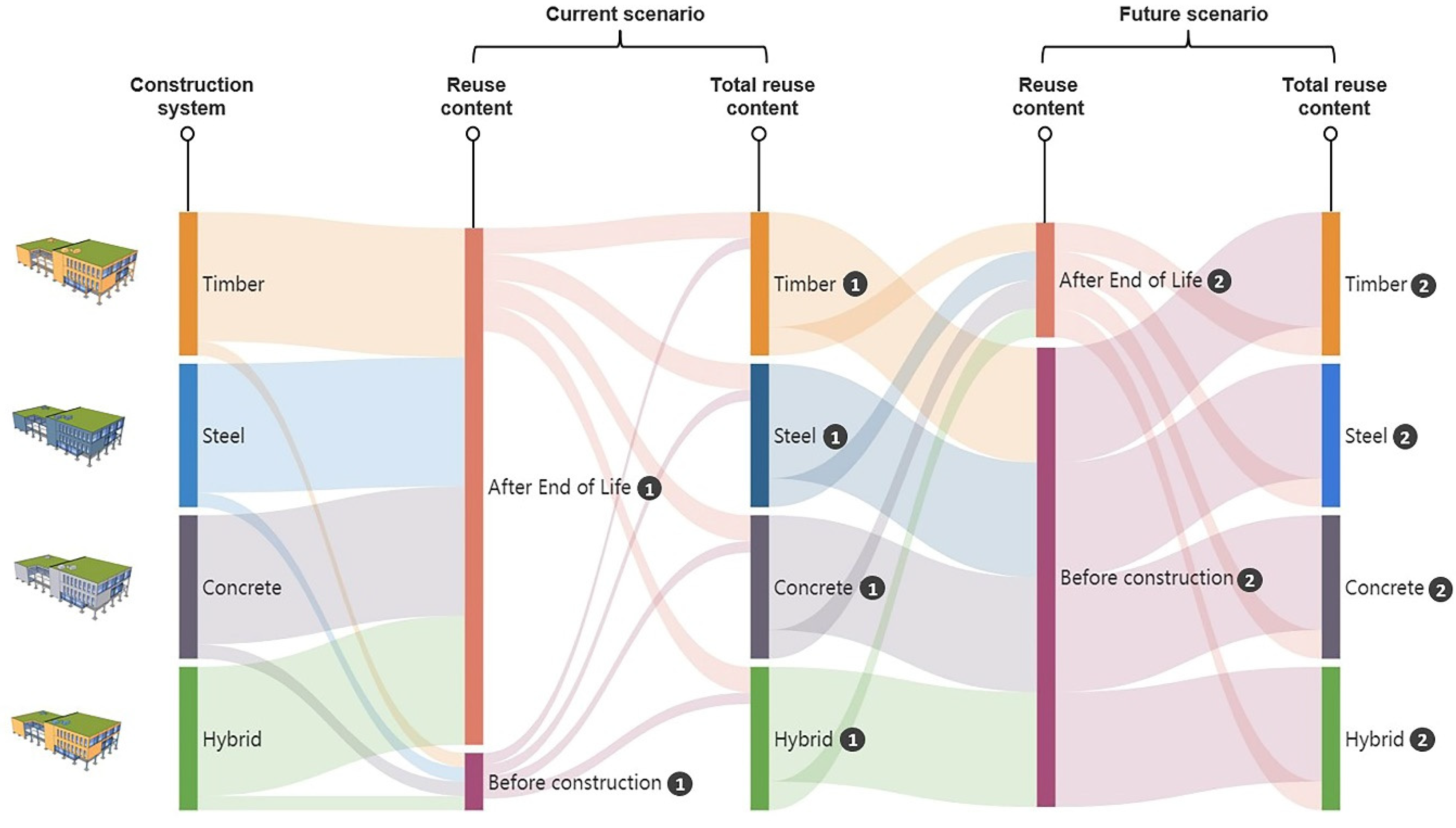

3.2. Reuse Content

- Before construction will be 80% of total reuse content.

- After the end of life will be 20% of total reuse content.

3.3. Land Use Footprint

3.4. Sensitivity Analysis

3.5. Uncertainty Analysis

4. Discussion

4.1. Summary of Main Findings and Recommendations

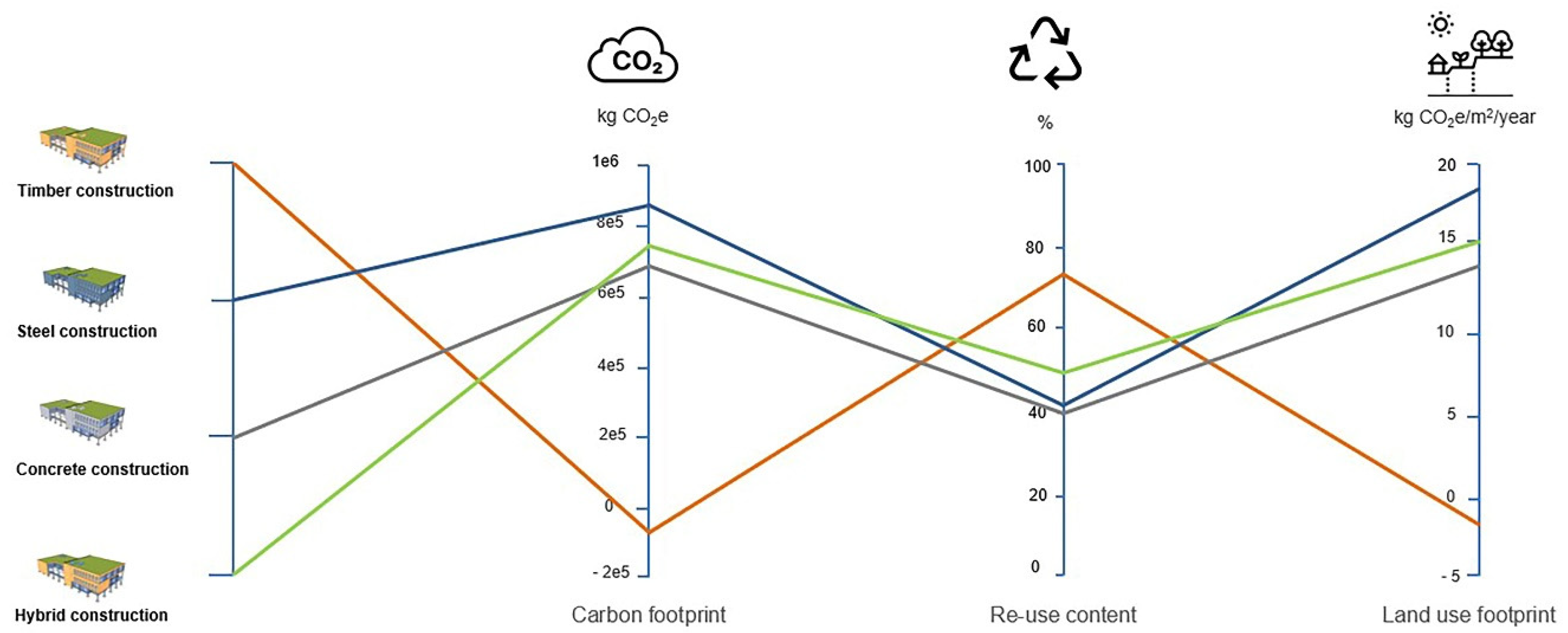

- Timber construction is better than other construction systems; carbon emissions of timber construction are three times less than concrete, and hybrid construction and four times less than steel construction (see Table 5).

- The biogenic carbon storage capacity of timber had the most significant effect in achieving this result based on a cradle to cradle calculation approach.

- The timber construction’s carbon emissions are lower than the requirements of the new French Building Regulation RE2020, which introduces a new threshold of 4 kg CO2e/m2 for new buildings [24].

- According to the circularity definition, this building is not a “reused building”, but we can call it a “reusable building” because the reused content before the construction is reaching 5%, but it will be 95% after the end of life and rebuilt in the other location.

- Regarding the land-use footprint, the timber construction achieved a negative value reaching (−1.3 kg CO2e/m2/year) for 20 years, unlike the other construction systems as shown in Figure 12.

- The consumption of electrical energy during the operation stage was one of the most influencing factors in increasing carbon emissions and global warming. As shown in Table 5, carbon emissions during the operational stage (B1–B7) reached 323,447.58 kg CO2 in the original Kamp C scenario (Timber construction). The sensitivity analysis and uncertainty analysis indicate that operational energy use significantly contributes to the environmental life cycle impact, in line with studies found in the literature [89,90].

- Designers should increase the materials reused content to achieve the highest circularity value. In Belgium, for example, it is challenging to use reclaimed and reused materials because of the lack of compliance and certification of those second-life materials. The construction industry in Belgium is heavily standardized and does not encourage building designers to use reclaimed building elements or materials.

- LCA must be based on dynamic enviornmental impact characterization factors and combined with circularity principles [91]. For ‘t Centrum project a digital twin will be created to allow for a digital twins-based LCA.

- To avoid falling into the greenwashing trap, we advise not to use any material that does not have an EPD. Many industrial manufacturers claim the sustainability of new and green materials, including low-impact concrete or products that have no EPDs.

- Scientists should develop simple evaluation methods and audits for reusing building elements, which can characterize building components or structural elements based on fatigue, durability, and duration of its second or third extended life.

4.2. Strengths and Limitations of This Research

4.3. Future Work and Possible Applications

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ellen MacArthur Foundation. Completing the Picture: How the Circular Economy Tackles Climate Change. Available online: https://ellenmacarthurfoundation.org/completing-the-picture (accessed on 9 December 2021).

- Sánchez-Garrido, A.J.; Navarro, I.J.; Yepes, V. Multi-criteria decision-making applied to the sustainability of building structures based on Modern Methods of Construction. J. Clean. Prod. 2022, 330, 129724. [Google Scholar] [CrossRef]

- Attia, S. Regenerative and Positive Impact Architecture; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Heisel, F.; Rau-Oberhuber, S. Calculation and evaluation of circularity indicators for the built environment using the case studies of UMAR and Madaster. J. Clean. Prod. 2019, 243, 118482. [Google Scholar] [CrossRef]

- Cottafava, D.; Ritzen, M. Circularity indicator for residential buildings: Addressing the gap between embodied impacts and design aspects. Resour. Conserv. Recycl. 2021, 164, 105120. [Google Scholar] [CrossRef]

- Çimen, Ö. Construction and built environment in circular economy: A comprehensive literature review. J. Clean. Prod. 2021, 305, 127180. [Google Scholar] [CrossRef]

- Al-Obaidy, M.; Santos, M.C.; Baskar, M.; Attia, S. Assessment of the circularity and carbon neutrality of an office building: The case of’t Centrum in Westerlo, Belgium. IOP Conf. Ser. Earth Environ. Sci. 2021, 855, 012025. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Rechberger, H. Concept for a BIM-based Material Passport for buildings. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012073. [Google Scholar] [CrossRef]

- Durmiševic, E. Reversible building design. In Designing for the Circular Economy, 1st ed.; Charter, M., Ed.; Routledge: Abingdon, UK; New York, NY, USA, 2018; pp. 344–359. [Google Scholar] [CrossRef]

- Nuñez-Cacho, P.; Górecki, J.; Molina-Moreno, V.; Corpas-Iglesias, F.A. What Gets Measured, Gets Done: Development of a Circular Economy Measurement Scale for Building Industry. Sustainability 2018, 10, 2340. [Google Scholar] [CrossRef] [Green Version]

- Tallini, A.; Cedola, L. A review of the properties of recycled and waste materials for energy refurbishment of existing buildings towards the requirements of NZEB. Energy Procedia 2018, 148, 868–875. [Google Scholar] [CrossRef]

- Passer, A.; Lasvaux, S.; Allacker, K.; De Lathauwer, D.; Spirinckx, C.; Wittstock, B.; Kellenberger, D.; Gschösser, F.; Wall, J.; Wallbaum, H. Environmental product declarations entering the building sector: Critical reflections based on 5 to 10 years experience in different European countries. Int. J. Life Cycle Assess. 2015, 20, 1199–1212. [Google Scholar] [CrossRef] [Green Version]

- Baldo, G.L.; Cesarei, G.; Minestrini, S.; Sordi, L. 6—The EU Ecolabel scheme and its application to construction and building materials. In Eco-Efficient Construction and Building Materials; Pacheco-Torgal, F., Cabeza, L.F., Labrincha, J., de Magalhães, A., Eds.; Woodhead Publishing: Cambridge, UK, 2014; pp. 98–124. [Google Scholar] [CrossRef]

- Cambier, C.; Galle, W.; De Temmerman, N. Research and Development Directions for Design Support Tools for Circular Building. Buildings 2020, 10, 142. [Google Scholar] [CrossRef]

- Rios, F.C.; Chong, W.K.; Grau, D. Design for Disassembly and Deconstruction—Challenges and Opportunities. Procedia Eng. 2015, 118, 1296–1304. [Google Scholar] [CrossRef] [Green Version]

- Cordero, A.S.; Melgar, S.G.; Márquez, J.M.A. Green Building Rating Systems and the New Framework Level(s): A Critical Review of Sustainability Certification within Europe. Energies 2020, 13, 66. [Google Scholar] [CrossRef] [Green Version]

- Attia, S.; Al-Obaidy, M. Design Criteria for Circular Buildings; Zuyd Uninversity: Parkstadt, The Netherlands, 2021; p. 11. [Google Scholar]

- Smol, M.; Duda, J.; Czaplicka-Kotas, A.; Szołdrowska, D. Transformation towards Circular Economy (CE) in Municipal Waste Management System: Model Solutions for Poland. Sustainability 2020, 12, 4561. [Google Scholar] [CrossRef]

- Smol, M. Inventory and Comparison of Performance Indicators in Circular Economy Roadmaps of the European Countries. Circ. Econ. Sustain. 2021. [Google Scholar] [CrossRef]

- Grover, R. Towards Zero Carbon Buildings: Reducing the Embodied Carbon Footprint of a Construction. 2020. Available online: https://repository.tudelft.nl/islandora/object/uuid%3A98e2c46c-7321-4eab-9f88-c3d10912003a (accessed on 19 July 2021).

- Huberman, N.; Pearlmutter, D. A life-cycle energy analysis of building materials in the Negev desert. Energy Build. 2008, 40, 837–848. [Google Scholar] [CrossRef]

- WGBC. Bringing Embodied Carbon Upfront. World Green Building Council. Available online: https://www.worldgbc.org/news-media/bringing-embodied-carbon-upfront (accessed on 26 July 2021).

- Dezeen. French Public Buildings to Be Built with 50 Per Cent Wood. Available online: https://www-dezeen-com.cdn.ampproject.org/c/s/www.dezeen.com/2020/02/12/france-public-buildings-sustainability-law-50-per-cent-wood/amp/ (accessed on 27 July 2021).

- Ministère de la Transition Écologique. RE2020: Une Nouvelle Étape vers une Future Règlementation Environnementale des Bâtiments Neufs Plus Ambitieuse Contre le Changement Climatique. Ministère de la Transition Écologique. Available online: https://www.ecologie.gouv.fr/re2020-nouvelle-etape-vers-future-reglementation-environnementale-des-batiments-neufs-plus (accessed on 26 July 2021).

- Rossi, B.; Marique, A.-F.; Reiter, S. Life-cycle assessment of residential buildings in three different European locations, case study. Build. Environ. 2012, 51, 402–407. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. What Is a Circular Economy? Available online: https://ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview (accessed on 9 January 2022).

- ISO. ISO 14040:2006: Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/03/74/37456.html (accessed on 19 July 2021).

- ISO. ISO 14044:2006: Environmental Management—Life Cycle Assessment—Requirements and Guidelines. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/03/84/38498.html (accessed on 19 July 2021).

- EN 15978:2011. Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. iTeh Standards Store. Available online: https://standards.iteh.ai/catalog/standards/cen/62c22cef-5666-4719-91f9-c21cb6aa0ab3/en-15978-2011 (accessed on 19 July 2021).

- One Click LCA. Calculate Your Environmental Impacts in Minutes. One Click LCA® Software. Available online: https://www.oneclicklca.com/ (accessed on 19 July 2021).

- OVAM. Totem: Tool to Optimise the Total Environmental Impact of Materials. Available online: https://www.ovam.be/materiaalprestatie-gebouwen-0 (accessed on 24 July 2021).

- OVAM. Annex. Monetisation of the MMG Method. Update 2017. Available online: https://www.vlaanderen.be/publicaties/annex-monetisation-of-the-mmg-method-update-2017 (accessed on 21 July 2021).

- EnergyPlus. Available online: https://energyplus.net/ (accessed on 21 July 2021).

- EPB-Eisen. Available online: https://www.energiesparen.be/epb-pedia/epb-eisen (accessed on 21 July 2021).

- Reap, J.; Roman, F.; Duncan, S.; Bras, B. A survey of unresolved problems in life cycle assessment. Int. J. Life Cycle Assess. 2008, 13, 374–388. [Google Scholar] [CrossRef]

- One Click LCA. LCA Database of Building Products: Local and Global Data for Your LCA. One Click LCA® software. Available online: https://www.oneclicklca.com/support/faq-and-guidance/documentation/database/ (accessed on 19 July 2021).

- Rakhshan, K.; Morel, J.-C.; Alaka, H.; Charef, R. Components reuse in the building sector—A systematic review. Waste Manag. Res. J. A Sustain. Circ. Econ. 2020, 38, 347–370. [Google Scholar] [CrossRef]

- Ritzen, M.; Van Oorschot, J.; Cammans, M.; Segers, M.; Wieland, T.; Scheer, P.; Creugers, B.; Abujidi, N. Circular (de)construction in the Superlocal project. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012048. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Ajayi, S.O.; Bilal, M.; Alaka, H.A.; Owolabi, H.A.; Bello, S.A.; Jaiyeoba, B.E.; Kadiri, K.O. Design for Deconstruction (DfD): Critical success factors for diverting end-of-life waste from landfills. Waste Manag. 2017, 60, 3–13. [Google Scholar] [CrossRef]

- Tingley, D.D.; Davison, B. Design for deconstruction and material reuse. Proc. Inst. Civ. Eng. Energy 2011, 164, 195–204. [Google Scholar] [CrossRef]

- Kalyun, M.; Wodajo, T. Application of a Design Method for Manufacture and Assembly, Flexible Assembly Methods and Their Evaluation for the Construction of Bridges. Undefined. 2012. Available online: https://www.semanticscholar.org/paper/Application-of-a-Design-Method-for-Manufacture-and-Kalyun-Wodajo/17f0e56185797c39d9789c07544a4fdab9212bed (accessed on 28 October 2021).

- Vandervaeren, C.; Galle, W.; Stephan, A.; De Temmerman, N. More than the sum of its parts: Considering interdependencies in the life cycle material flow and environmental assessment of demountable buildings. Resour. Conserv. Recycl. 2022, 177, 106001. [Google Scholar] [CrossRef]

- Standards, E. EN 15804+A2. Available online: https://www.en-standard.eu/csn-en-15804-a2-sustainability-of-construction-works-environmental-product-declarations-core-rules-for-the-product-category-of-construction-products/ (accessed on 18 August 2021).

- One Click LCA. How Do I Model Module D for Recycled Material? One Click LCA Help Centre. Available online: https://oneclicklca.zendesk.com/hc/en-us/articles/360022222720-How-Do-I-Model-Module-D-For-Recycled-Material- (accessed on 15 December 2021).

- EEA. The European Environment—State and Outlook 2020: Knowledge for Transition to a Sustainable Europe—European Environment Agency. Available online: https://www.eea.europa.eu/soer (accessed on 29 July 2021).

- European Committee for Standardization. Standard NBN EN 15221-6:2011. Available online: https://www.nbn.be/shop/en/standard/nbn-en-15221-6-2011_20688/# (accessed on 23 July 2021).

- Beneens. We Build Camp Circular. Beneens. Available online: https://www.beneens.be/circulair (accessed on 19 July 2021).

- Binderholz GmbH. WOOD The Intelligent and Versatile Raw Material. binderholz.com. Available online: https://www.binderholz.com/?klenk= (accessed on 15 November 2021).

- ResourceFull. Low Carbon Concrete ResourceFull Houthalen-Helchteren. Available online: https://www.resourcefull.eu (accessed on 9 January 2022).

- ResourceFull. Foundationst Centrum Built without Cement. ResourceFull.eu. Available online: https://www.resourcefull.eu/tcentrum-kampc-cementless-foundations (accessed on 4 August 2021).

- Eurostat, Cooling and Heating Degree Days by NUTS 3 Regions—Annual Data; European Commission: Brussels, Belgium, 2021; Available online: https://ec.europa.eu/eurostat/databrowser/view/nrg_chddr2_a/default/table?lang=en (accessed on 8 January 2022).

- RMI. Royal Meteorological Institute of Belgium. 2021. Available online: https://www.meteo.be/en/belgium (accessed on 8 January 2022).

- Taleghani, M.; Marshall, A.; Fitton, R.; Swan, W. Renaturing a microclimate: The impact of greening a neighbourhood on indoor thermal comfort during a heatwave in Manchester, UK. Sol. Energy 2019, 182, 245–255. [Google Scholar] [CrossRef]

- Caleys, L. Comparing the Energy Performance and Sustainability of Vacuum Insulated Glass vs. Triple Glass in an Office Building: A Case Study in Belgium. Master’s Thesis, Liege University, Liege, Belgium, 2022. [Google Scholar]

- Meex, E. Early Design Support for Material Related Environmental Impact Assessment of Dwellings. 2018. Available online: https://documentserver.uhasselt.be//handle/1942/27512 (accessed on 31 July 2021).

- Roos Servaes, TOTEM & Circulariteit. Roos Servaes Masterclass Kamp C, 4 Oktober PDF Gratis Download. Available online: https://docplayer.nl/131574855-Totem-circulariteit-roos-servaes-masterclass-kamp-c-4-oktober-2018.html (accessed on 24 October 2021).

- Gobbo, E.; Ghyoot, M.; Paduart, A.; Nasseredine, M. Reuse in Environmental Impact Assessment Tools. 2021. Available online: https://www.nweurope.eu/media/15802/reuse_in_environmental_impact_assessment_tools_2021.pdf (accessed on 10 December 2021).

- E-Peil: Eis Voor Niet-Residentiële Gebouwen, Vlaanderen is Energie. 2021. Available online: https://www.energiesparen.be/epb-pedia/e-peil/eis-niet-residentieel-2021 (accessed on 19 July 2021).

- Attia, S. Net Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and Implementation; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Blom, I.; Itard, L.; Meijer, A. Environmental impact of building-related and user-related energy consumption in dwellings. Build. Environ. 2011, 46, 1657–1669. [Google Scholar] [CrossRef]

- Collinge, W.O.; Landis, A.E.; Jones, A.K.; Schaefer, L.A.; Bilec, M.M. Dynamic life cycle assessment: Framework and application to an institutional building. Int. J. Life Cycle Assess. 2012, 18, 538–552. [Google Scholar] [CrossRef]

- EnergyVille. Belgian Long Term Electricity System Scenarios. Available online: https://www.energyville.be/belgian-long-term-electricity-system-scenarios (accessed on 29 September 2021).

- Federaal Planbureau—Publicatie—Het Belgische Energielandschap Tegen 2050—Een Projectie Bij Ongewijzigd Beleid. Available online: https://www.plan.be/publications/publication-1728-nl-het_belgische_energielandschap_tegen_2050_een_projectie_bij_ongewijzigd_beleid (accessed on 4 September 2021).

- Ramon, D.; Allacker, K. Integrating long term temporal changes in the Belgian electricity mix in environmental attributional life cycle assessment of buildings. J. Clean. Prod. 2021, 297, 126624. [Google Scholar] [CrossRef]

- ENGIE Electrabel. Radioactive Waste. ENGIE Electrabel. Available online: https://nuclear.engie-electrabel.be/en/nuclear-energy/nuclear-power-plants-and-climate/radioactive-waste (accessed on 26 October 2021).

- VEB. Vlaams Energiebedrijf, Efficiënt in Energie. Available online: https://www.veb.be/ (accessed on 17 October 2021).

- Vlaanderen. Vlaams Energiebedrijf. Available online: https://www.vlaanderen.be/organisaties/administratieve-diensten-van-de-vlaamse-overheid/beleidsdomein-omgeving/vlaams-energiebedrijf (accessed on 28 October 2021).

- Al-Obaidy, M.; Attia, S. Environmental Product Declaration Dataset of ’t Centrum Circular Building in Westerlo, Belgium. Harvard Dataverse, 23 January 2022. Available online: https://dataverse.harvard.edu/dataset.xhtml?persistentId=doi:10.7910/DVN/Z1CS97 (accessed on 23 January 2022).

- One Click LCA. How We Work with Data at One Click LCA. One Click LCA® Software. Available online: https://www.oneclicklca.com/how-we-work-with-data-at-one-click-lca/ (accessed on 21 July 2021).

- Meex, E.; Hollberg, A.; Knapen, E.; Hildebrand, L.; Verbeeck, G. Requirements for applying LCA-based environmental impact assessment tools in the early stages of building design. Build. Environ. 2018, 133, 228–236. [Google Scholar] [CrossRef]

- Li, Y.; Allacker, K.; Feng, H.; Heidari, M.D.; Pelletier, N. Net zero energy barns for industrial egg production: An effective sustainable intensification strategy? J. Clean. Prod. 2021, 316, 128014. [Google Scholar] [CrossRef]

- Byggeriets Materialepyramide. Available online: https://www.materialepyramiden.dk/ (accessed on 7 December 2021).

- Larivière-Lajoie, R.; Blanchet, P.; Amor, B. Evaluating the importance of the embodied impacts of wall assemblies in the context of a low environmental impact energy mix. Build. Environ. 2022, 207, 108534. [Google Scholar] [CrossRef]

- Grosso, M.; Thiebat, F. Life Cycle Environmental Assessment of Temporary Building Constructions. Energy Procedia 2015, 78, 3180–3185. [Google Scholar] [CrossRef] [Green Version]

- Huijbregts, M.A.J.; Gilijamse, W.; Ragas, A.M.J.; Reijnders, L. Evaluating Uncertainty in Environmental Life-Cycle Assessment. A Case Study Comparing Two Insulation Options for a Dutch One-Family Dwelling. Environ. Sci. Technol. 2003, 37, 2600–2608. [Google Scholar] [CrossRef] [PubMed]

- Cellura, M.; Longo, S.; Mistretta, M. Sensitivity analysis to quantify uncertainty in Life Cycle Assessment: The case study of an Italian tile. Renew. Sustain. Energy Rev. 2011, 15, 4697–4705. [Google Scholar] [CrossRef]

- Vlaanderen Circulair. Circular Retrofit Lab. Vlaanderen Circulair. Available online: https://vlaanderen-circulair.be/en/cases/detail/circular-retrofit-lab (accessed on 5 November 2021).

- Archipelago. Joseph Bracops Hospital, Anderlecht: An Urban Hospital Based on Circular Economy Principles. Archipelago. Available online: https://archipelago.be/en/projects/how-can-we-design-an-urban-hospital-according-to-circular-economy-principles/ (accessed on 5 November 2021).

- OPALIS. L’Institut de Botanique de l’ULg. Opalis. Available online: https://opalis.eu/fr/projets/linstitut-de-botanique-de-lulg (accessed on 5 November 2021).

- AGC Glass, AGC Glass Belgium. AGC Belgium—Glas—Beglazing—Pyrobel—WBDBO. Available online: https://www.agcglassbelgium.be/ (accessed on 5 November 2021).

- ROTOR, Rotor—Brussels Rotor. Available online: http://rotordb.org/en (accessed on 5 November 2021).

- Allacker, K.; Debacker, W.; Delem, L.; De Nocker, L.; De Troyer, F.; Janssen, A.; Peeters, K.; Servaes, R.; Spirinckx, C.; Van Dessel, J. Environmental Profile of Building Elements [Update 2020], Danny Wille, OVAM.; Stationsstraat 110, 2800 Mechelen, 2020. Available online: https://lirias.kuleuven.be/1954287 (accessed on 9 November 2021).

- Kamp, C. Circular Building: ’t Centrum. Available online: https://www.kampc.be/tcentrum/circulair-bouwen-t-centrum (accessed on 19 July 2021).

- Goffart, J.; Woloszyn, M. EASI RBD-FAST: An efficient method of global sensitivity analysis for present and future challenges in building performance simulation. J. Build. Eng. 2021, 43, 103129. [Google Scholar] [CrossRef]

- Saltelli, A.; Aleksankina, K.; Becker, W.; Fennell, P.; Ferretti, F.; Holst, N.; Li, S.; Wu, Q. Why so many published sensitivity analyses are false: A systematic review of sensitivity analysis practices. Environ. Model. Softw. 2019, 114, 29–39. [Google Scholar] [CrossRef]

- Saltelli, A.; Sobol’, I.M. Sensitivity analysis for nonlinear mathematical models: Numerical experience. Mat. Modelirovanie 1995, 7, 16–28. [Google Scholar]

- Baubook. Binderholz Brettsperrholz BBS (Fichte). Available online: https://www.baubook.at/vlbg/?URL_R=https%3A%2F%2Fwww.baubook.at%2Fm%2FPHP%2FInfo.php%3FSI%3D2142705769%26SW%3D2&SW=2 (accessed on 15 November 2021).

- Ecoschelp. Bouw en Bescherm Met Schelpen. Available online: https://www.ecoschelp.be/nl/ (accessed on 14 November 2021).

- Decorte, Y.; Steeman, M.; Bossche, N.V.D. Effect of a one-dimensional approach in LCA on the environmental life cycle impact of buildings: Multi-family case study in Flanders. Build. Environ. 2021, 206, 108381. [Google Scholar] [CrossRef]

- Giordano, R.; Serra, V.; Demaria, E.; Duzel, A. Embodied Energy Versus Operational Energy in a Nearly Zero Energy Building Case Study. Energy Procedia 2017, 111, 367–376. [Google Scholar] [CrossRef] [Green Version]

- Levasseur, A.; Lesage, P.; Margni, M.; Deschênes, L.; Samson, R. Considering Time in LCA: Dynamic LCA and Its Application to Global Warming Impact Assessments. Environ. Sci. Technol. 2010, 44, 3169–3174. [Google Scholar] [CrossRef]

- Helal, J.; Stephan, A.; Crawford, R.H. The influence of structural design methods on the embodied greenhouse gas emissions of structural systems for tall buildings. Structures 2020, 24, 650–665. [Google Scholar] [CrossRef]

- Manfren, M.; Tagliabue, L.C.; Cecconi, F.R.; Ricci, M. Long-Term Techno-Economic Performance Monitoring to Promote Built Environment Decarbonisation and Digital Transformation—A Case Study. Sustainability 2022, 14, 644. [Google Scholar] [CrossRef]

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.K.; Graedel, T.E.; Schellnhuber, H.J. Buildings as a global carbon sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

- Robati, M.; Oldfield, P.; Nezhad, A.A.; Carmichael, D.G.; Kuru, A. Carbon value engineering: A framework for integrating embodied carbon and cost reduction strategies in building design. Build. Environ. 2021, 192, 107620. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Chinyio, E.A.; Olomolaiye, P.O. Design of A Sustainable Building: A Conceptual Framework for Implementing Sustainability in the Building Sector. Buildings 2012, 2, 126–152. [Google Scholar] [CrossRef] [Green Version]

- VITO. Demolition Guide Recognizes Building Materials for Recycling or Reuse. Available online: https://vito.be/en/news/demolition-guide-recognizes-building-materials-recycling-or-reuse (accessed on 9 December 2021).

- CEN/TC 350, CEN/TC 350/SC 1—Circular Economy in the Construction Sector. iTeh Standards Store. Available online: https://standards.iteh.ai/catalog/tc/cen/51316ef3-3dea-4483-8aab-cd1a8033cd41/cen-tc-350-sc-1 (accessed on 12 December 2021).

- ISO, ISO/TC 323—Circular Economy (under Development). ISO. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/committee/72/03/7203984.html (accessed on 12 December 2021).

| Architect | Design & Engineering | Structural Engineering | Constructor | Constructing with Green & Natural Elements | Geothermal Energy | EPB Reporting | Concrete Technology | Research |

|---|---|---|---|---|---|---|---|---|

| West Architecture | TEN-agency | Streng-th | Beneens | Muurtuin | Tenerga | VESTAD | ResourceFull | VITO |

| Building Material Category | Timber Construction | Steel Construction | Concrete Construction | Hybrid Construction | ||||

|---|---|---|---|---|---|---|---|---|

| Amount (kg) | Share (%) | Amount (kg) | Share (%) | Amount (kg) | Share (%) | Amount (kg) | Share (%) | |

| Timber | 216,585 | 27 | ✕ | ✕ | ✕ | ✕ | 12,324 | 0.91 |

| Steel | 2800 | 0.35 | 312,881 | 20.65 | 42,852 | 2.44 | 71,479 | 5.28 |

| Galvanized steel | 2210 | 0.28 | 2210 | 0.14 | 2210 | 0.12 | 2210 | 0.16 |

| Concrete | 135,000 | 17 | 780,464 | 51.51 | 1,303,213 | 74.31 | 863,325 | 63.87 |

| Gypsum | 5352 | 0.68 | 5352 | 0.35 | ✕ | ✕ | ✕ | ✕ |

| Carton grey boards | 8500 | 1.10 | 8500 | 0.56 | 8500 | 0.48 | 8500 | 0.62 |

| Aluminium | 2000 | 0.25 | 2000 | 0.06 | 2000 | 0.05 | 2000 | 0.07 |

| Glass (partitions) | 4500 | 0.57 | 4500 | 0.29 | 4500 | 0.25 | 4500 | 0.33 |

| Glass (windows & doors) | 31,352 | 4.02 | 31,352 | 2.06 | 27,452 | 1.56 | 22,400 | 1.65 |

| Wall insulation (Cellulose) | 5700 | 0.73 | ✕ | ✕ | ✕ | ✕ | ✕ | ✕ |

| Wall & floor insulation (Rockwool) | 3000 | 0.38 | 5300 | 0.35 | ✕ | ✕ | 3800 | 0.28 |

| Wall insulation (Polystyrene) | ✕ | ✕ | ✕ | ✕ | 2000 | 0.11 | ✕ | ✕ |

| Roof insulation (Pavatex) | 820 | 0.10 | 820 | 0.05 | 820 | 0.04 | 820 | 0.06 |

| Roof insulation (Steico) | 6200 | 0.79 | 6200 | 0.41 | 6200 | 0.35 | 6200 | 0.45 |

| Services and cables (copper, plastic, etc.) | 2000 | 0.25 | 2000 | 0.06 | 2000 | 0.05 | 2000 | 0.07 |

| Floor insulation (Shells) | 353,983 | 45.40 | 353,983 | 23.64 | 353,983 | 20.18 | 353,983 | 26.19 |

| Construction System | Calculation Period | CO2 Emissions | ||

|---|---|---|---|---|

| Embodied | Operation | Total | ||

| Timber | 20 years | −385,810 | 323,448 | −62,362 |

| 40 years | −507,077 | 646,895 | 244,528 | |

| 60 years | −628,344 | 970,343 | 487,609 | |

| Steel | 20 years | 542,269 | 323,448 | 865,717 |

| 40 years | 436,804 | 646,895 | 1,083,699 | |

| 60 years | 331,794 | 970,343 | 1,302,137 | |

| Concrete | 20 years | 331,483 | 323,448 | 654,930 |

| 40 years | 226,473 | 646,895 | 873,368 | |

| 60 years | 121,007 | 970,343 | 1,091,350 | |

| Hybrid | 20 years | 394,989 | 323,448 | 718,437 |

| 40 years | 289,524 | 646,895 | 936,419 | |

| 60 years | 184,059 | 970,343 | 1,154,402 | |

| Principle | Meaning in Practice |

|---|---|

| Availability | Revise and integrate all publicly and freely available LCA data that meet One Click LCA’s Data Quality Policy (DQP). |

| Plausibility (ref. EN 15978) [29] | Any market-based LCA data have to satisfy the Data Quality Policy (DQP) of One Click LCA to be included and used in the software. It covers ten steps and over 40 different checks. |

| Consistency (ref. EN 15978) [29] | LCA data consistency is ensured. If data include biogenic carbon storage, it is homogenized to ensure consistency of calculations (–) in One Click LCA’s non-regulated LCA tools, biogenic carbon is always reported as a separate set of results to ensure transparency and clarity. |

| Representativeness (UN Guidelines) | All data are comprehensively classified on geographical and time representativeness. The data are documented based on available information for technological representativeness as a textual description. |

| Transparency | The data are enriched with metadata and information, allowing for a better understanding of the data point and its quality. |

| Life Cycle Stages EN 15978 | Timber Construction | Steel Construction | Concrete Construction | Hybrid Construction |

|---|---|---|---|---|

| 20 Years Kamp C Scenario | 20 Years Proposed Scenario | 20 Years Proposed Scenario | 20 Years Proposed Scenario | |

| Biogenic carbon storage * | −385,086 | −11,506 | −11,506 | −30,686 |

| Product stage A1–A3 | 156,197 | 623,380 | 425,884 | 507,889 |

| Construction Stage A4–A5 | 108,503 | 111,608 | 110,319 | 110,290 |

| Use Stage B1–B7 | 323,448 | 323,448 | 323,448 | 323,448 |

| End-of-life Stage C1–C4 | 34,056 | 8314 | 8223 | 8112 |

| Re-use D * | −299,479 | −189,527 | −201,438 | −200,617 |

| Total life cycle | −62,362 | 865,717 | 654,930 | 718,436 |

| Impact Category | Unit | Alum ± 10% | Galv. Steel ± 10% | Copper ± 10% | Timber ± 10% | Concrete ± 10% | Building Lifespan | |

|---|---|---|---|---|---|---|---|---|

| + 20 Years | + 40 Years | |||||||

| Global Warming (GWP) | kg CO2e | ±0.8% | ±0.9% | ±0.3% | ±60% | ±01% | +392% | +781% |

| Acidification (AP) | kg SO2e | ±0.8% | ±0.4% | ±0.9% | ±2.5% | ±0.2% | +12% | +38% |

| Eutrophication (EP) | kg PO4e | ±0.01% | ±0.01% | ±0.17% | ±2.7% | - | +4.3% | +15% |

| Ozone depletion potential (ODP) | kg CFC11e | - | - | - | ±25% | - | - | +25% |

| Formation of ozone of lower atmosphere (POCP) | kg Ethenee | ±0.02% | - | ±0.02% | ±7% | - | +2.8% | +21% |

| Total use of primary energy ex. raw materials | MJ | ±1.6% | ±1.4% | ±1.4% | ±3.8% | - | +0.4% | +65% |

| Bio-CO2 storage | kg CO2e bio | - | - | - | ±8.6% | - | - | - |

| Land use footprint | kg CO2e/m2/year | ±0.08% | ±0.1% | ±0.03% | ±54% | - | +300% | +360% |

.

.Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Obaidy, M.; Courard, L.; Attia, S. A Parametric Approach to Optimizing Building Construction Systems and Carbon Footprint: A Case Study Inspired by Circularity Principles. Sustainability 2022, 14, 3370. https://doi.org/10.3390/su14063370

Al-Obaidy M, Courard L, Attia S. A Parametric Approach to Optimizing Building Construction Systems and Carbon Footprint: A Case Study Inspired by Circularity Principles. Sustainability. 2022; 14(6):3370. https://doi.org/10.3390/su14063370

Chicago/Turabian StyleAl-Obaidy, Muheeb, Luc Courard, and Shady Attia. 2022. "A Parametric Approach to Optimizing Building Construction Systems and Carbon Footprint: A Case Study Inspired by Circularity Principles" Sustainability 14, no. 6: 3370. https://doi.org/10.3390/su14063370

APA StyleAl-Obaidy, M., Courard, L., & Attia, S. (2022). A Parametric Approach to Optimizing Building Construction Systems and Carbon Footprint: A Case Study Inspired by Circularity Principles. Sustainability, 14(6), 3370. https://doi.org/10.3390/su14063370